Adwelds' ultrasonic bonding machines allow bonding heterogeneous metals at room temperature. Bonding time is less than one second which is a high productivity manufacturing process. Adwelds suggests clients various processing to utilize the advanced ultrasonic technology in their manufacturing process, which highly improves the clients’ production value. Adwelds ultrasonic bonding machines realize precise bonding by installing functions that control position alignment, advanced head pressure, and digital condition settings. In addition, a function that monitors the whole process allows the operator to manage the processing conditions and manufacturing procedures appropriately.

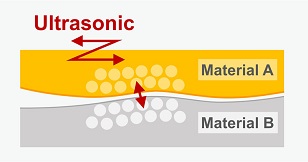

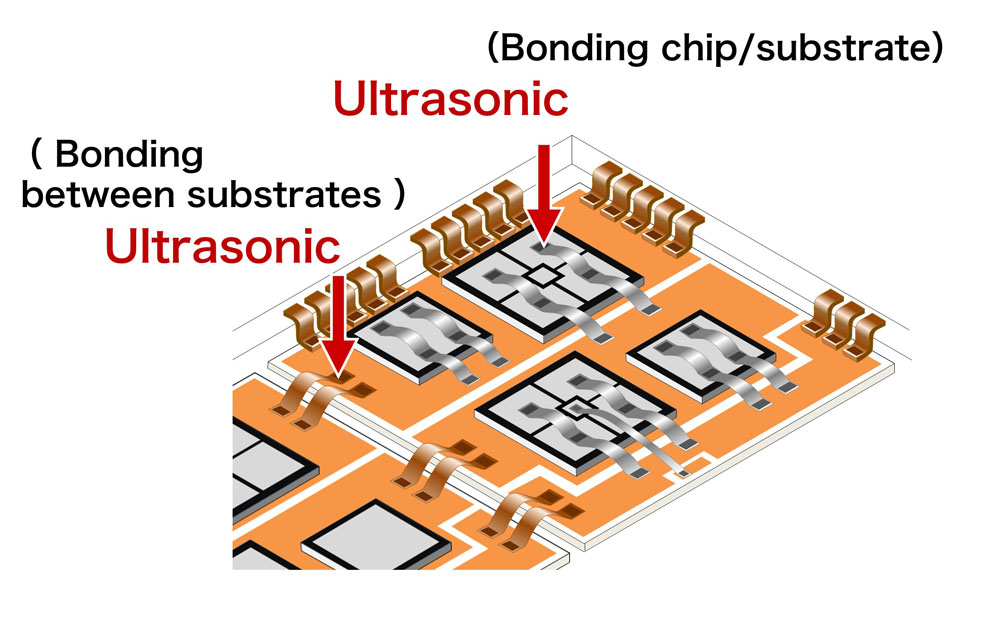

Homogeneous/Heterogeneous Metal Bonding

It bonds heterogeneous metals well, which was hard to achieve with conventional bonding method. Needless to solder, you can bond them directly at room temperature

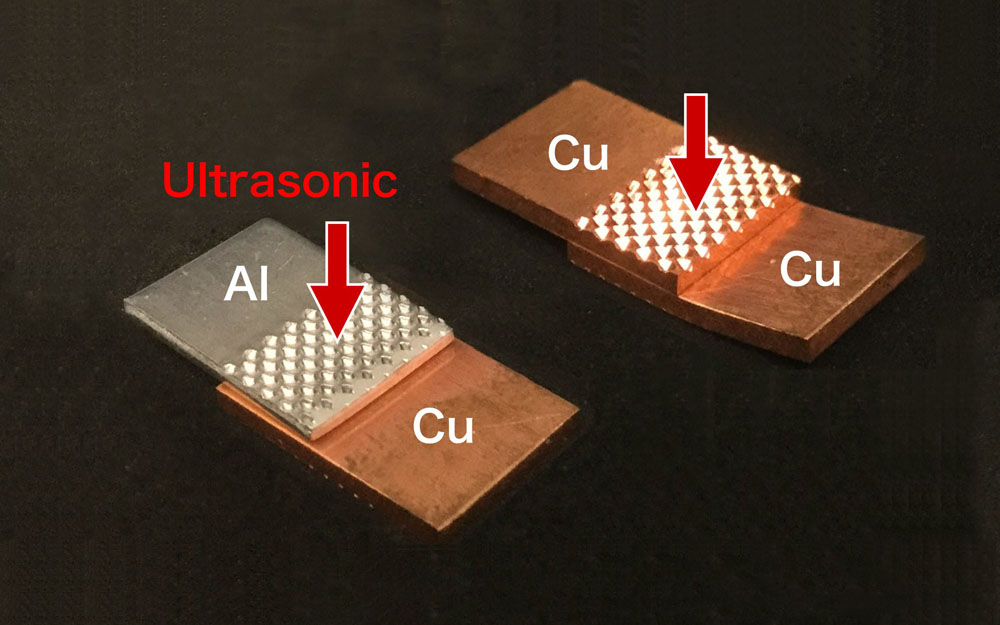

Li Ion Battery (Multi layer foils)

Li Ion batteries are weak to heat, but ultrasonic bonding allows bonding over 50 layered foils without heating

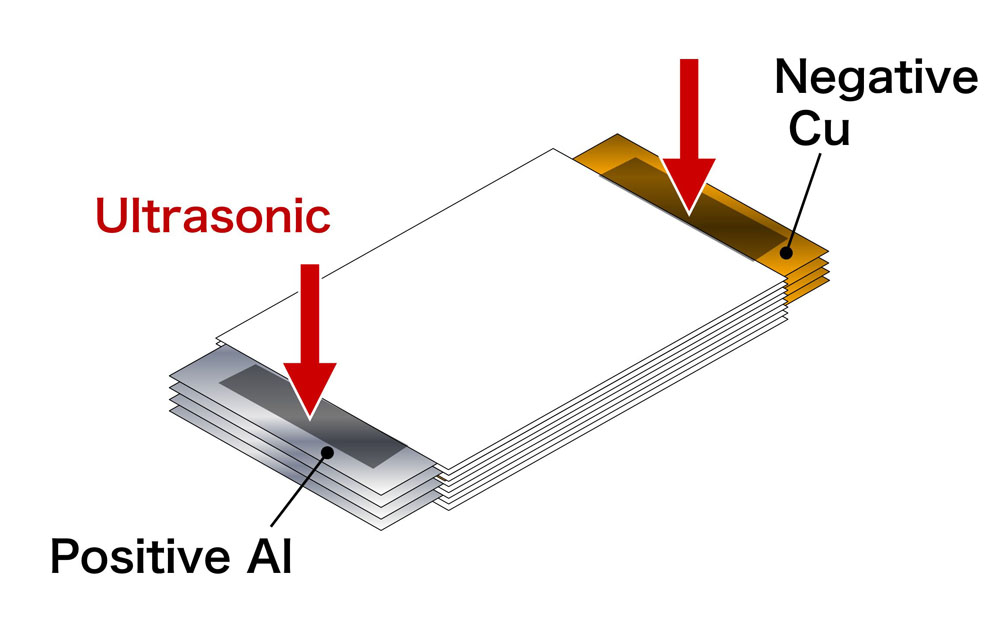

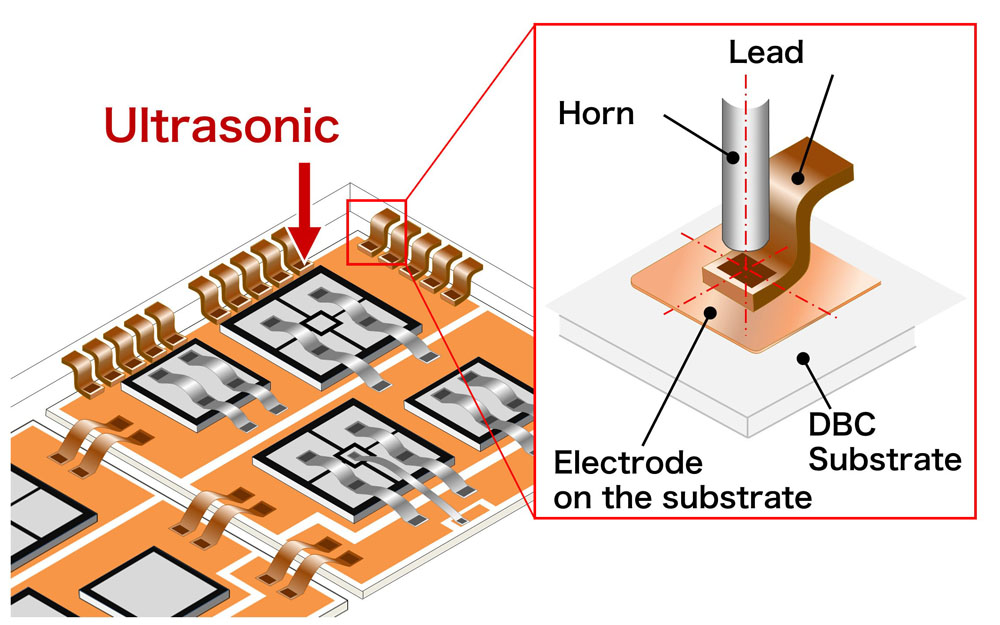

IGBT Module (Terminal bonding)

It is desirable to bond without soldering when dealing with IGBT module, which requires high temperature during operation. Ultrasonic bonds the lead on the package side and the electrode on the DBC substrate directly

IGBT Module (Ribbon Bonding)

Multiple kinds of ribbon bondings are available with multi-feeder

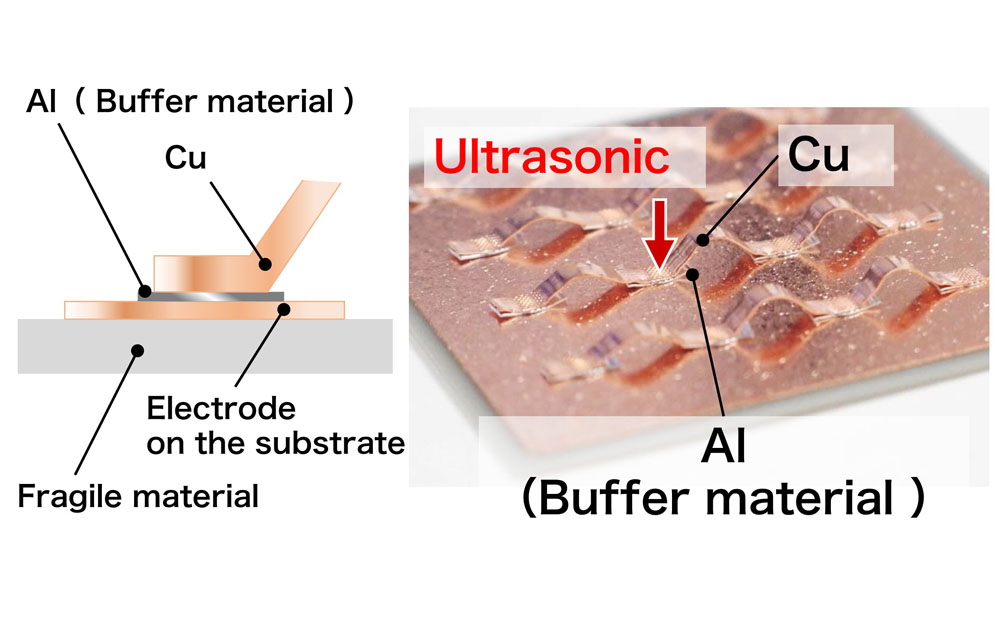

ABB Process

Cu ribbon bonding is available by using Al as a buffer material, it gives strength to a feeble base material

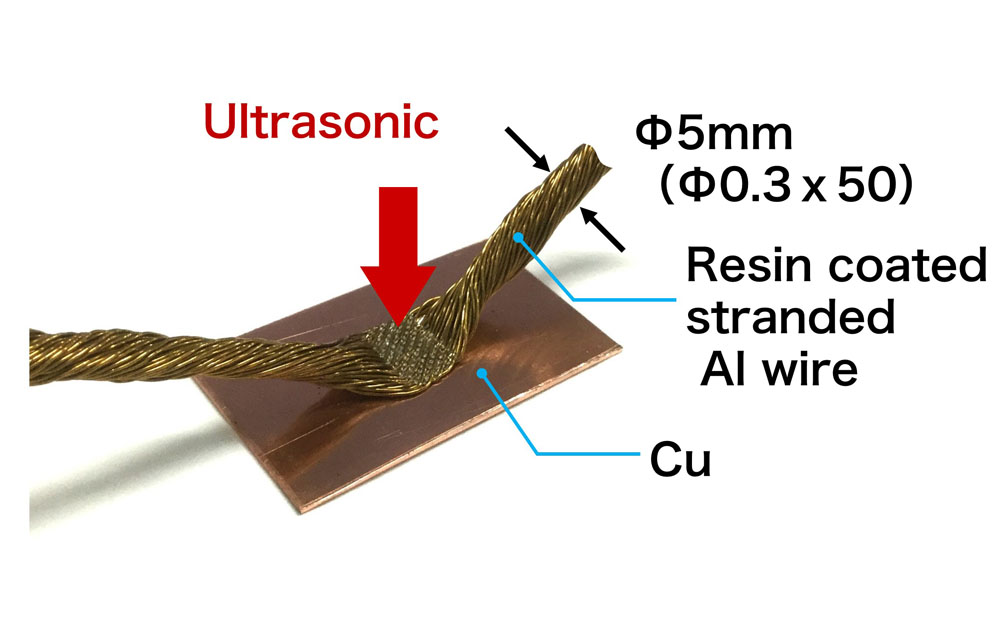

Bonding Coated Wire

After pressing down the coated wire, ultrasonic breaks the insulating layer and bonds the inner wire to an electrode directly

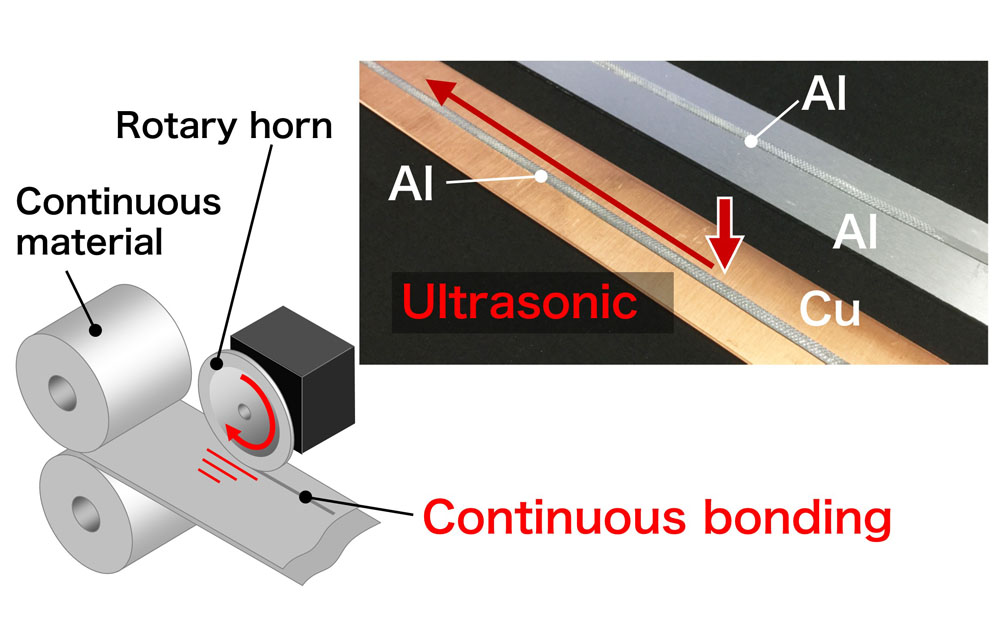

Continuous Metal Bonding

Use the rotary horn to bond a rolled type or similar kinds of rolled metal materials continuously

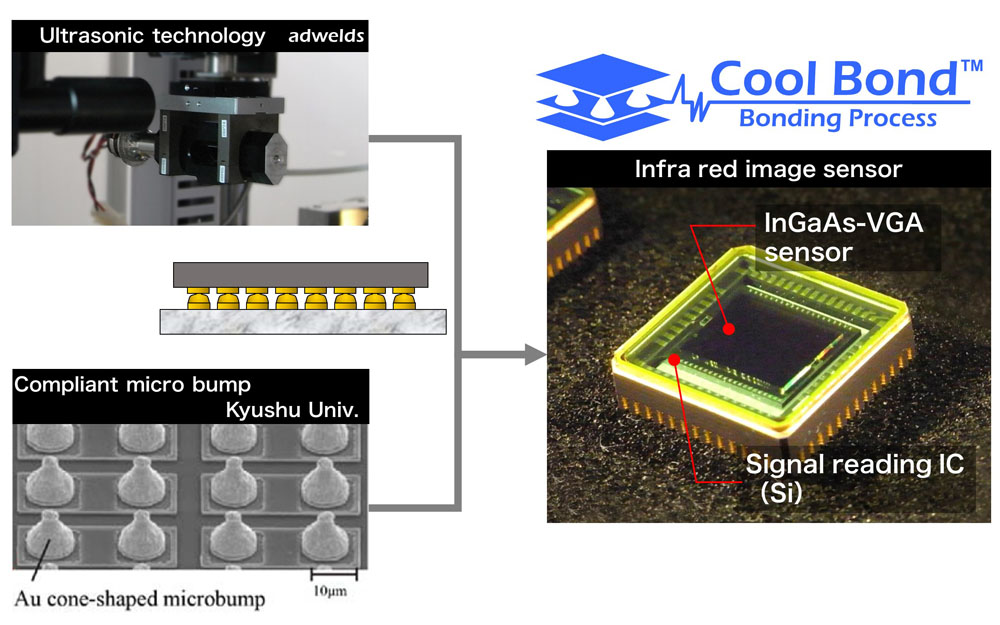

Infrared Image Sensor (Cool Bond)

Our ultrasonic bonding machine bonds 300,000 sharp-end bumps (Kyushu U) at once at room temperature, a collaboration with Kyushu University

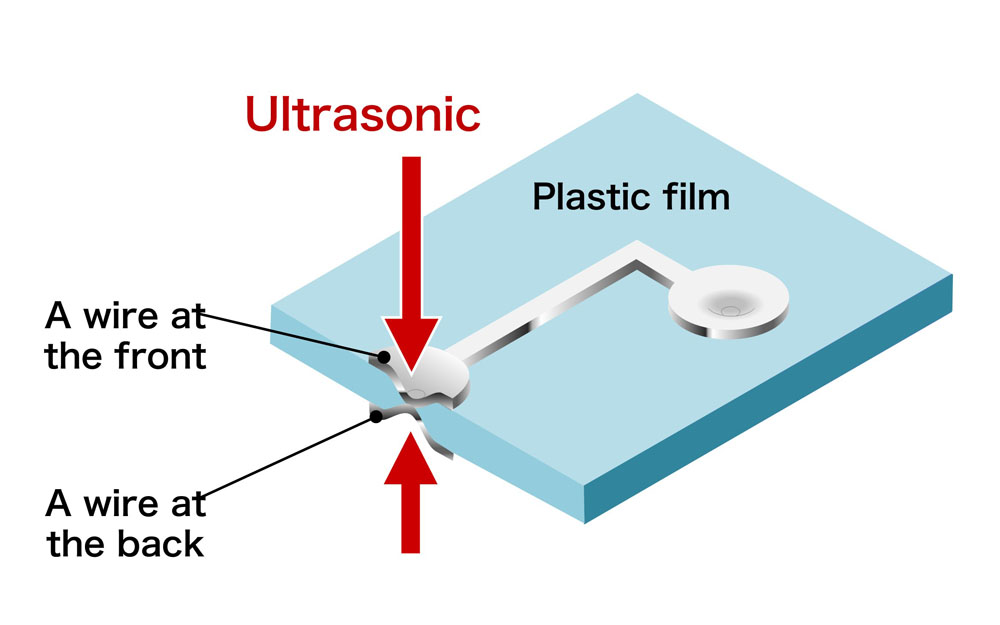

IC Card (Front and back pattern pierce bonding)

When pressing down the wirings on the resin film and apply ultrasonic, ultrasonic pierces the film, without pretreatment of via processing, it bonds the wires