Adwelds ultrasonic welding machine strongly welds thermoplastic resins. This machine changes ultrasonic energy to heat at the welding surface of an application. Adwelds' original technology allows continuous welding, not just spot welding like the conventional technology, so it will create clients’ new production value. Adwelds ultrasonic welding machines realize precise welding by installing functions that control position alignment, advanced head pressure, and digital condition settings. In addition, a function that monitors the whole process allows the operator to manage the processing conditions and manufacturing procedures appropriately.

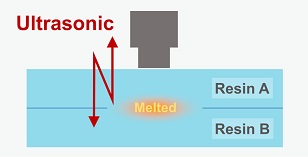

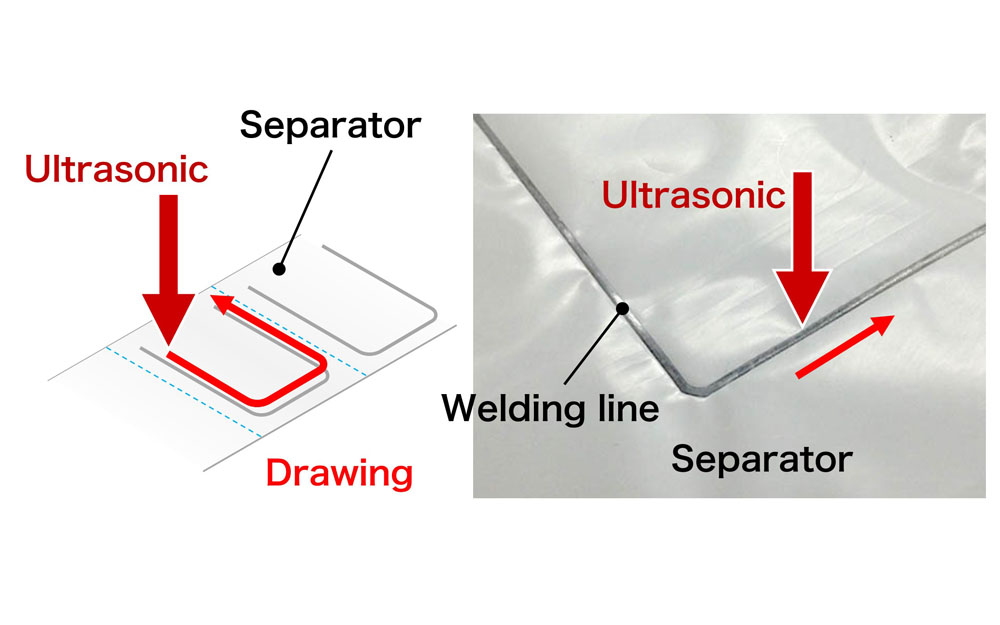

Li Ion Battery (Seperator Welding)

A seperator, which is weak to heat, can be welded by pressing (the pressed part only dissolves) and applying ultrasonic without heating

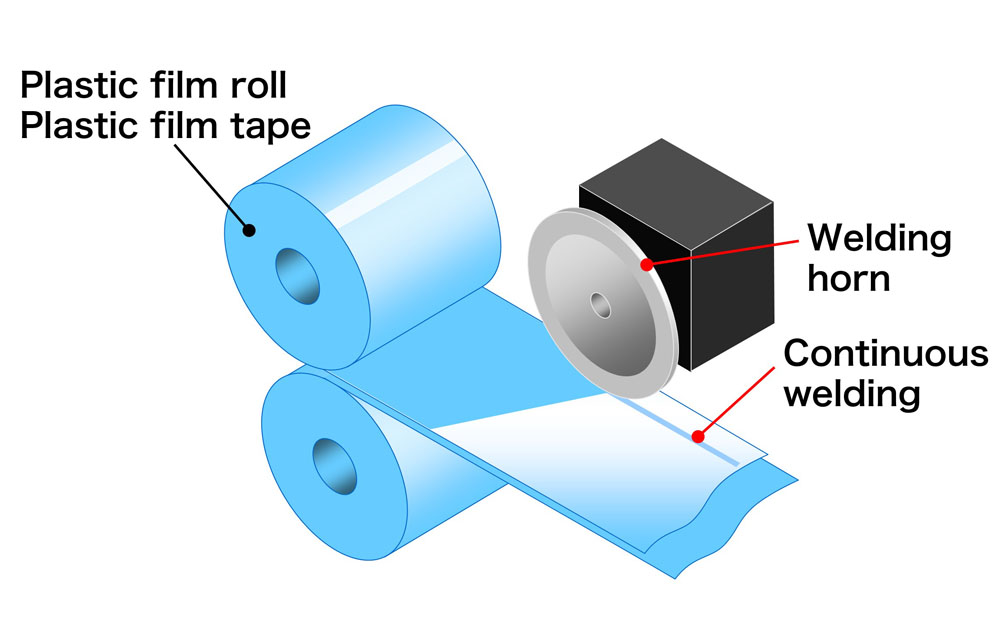

Continuous Welding

Use a rotary horn and weld a roll type resin material continuously

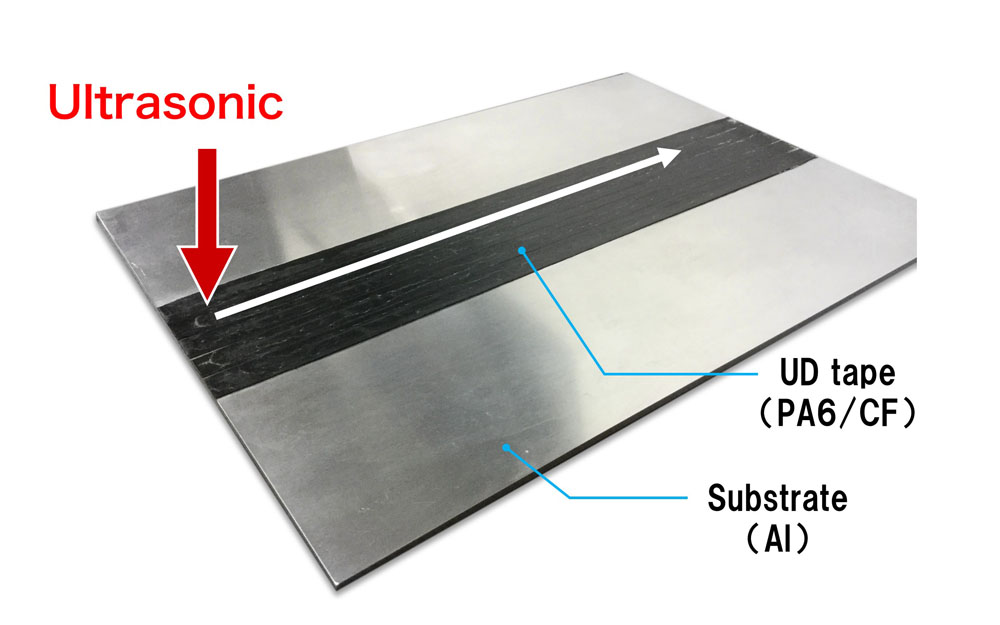

Multi Material Continuous Welding

You can weld metal applications, such as aluminum, on a UD tape continuously and gain high rigidity, unlike the conventional spot welding

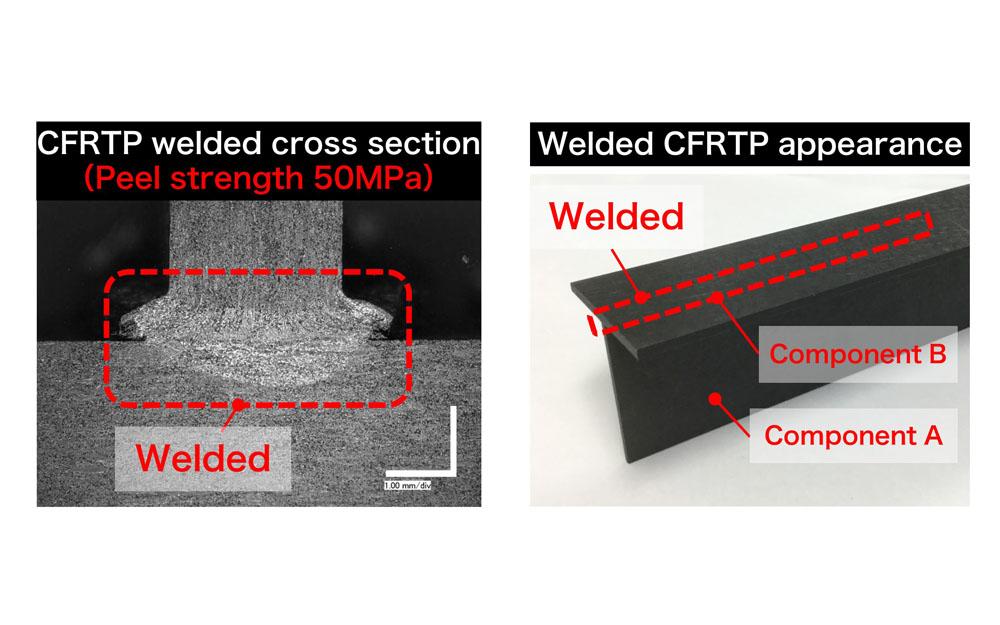

CFRTP Component Continuous Welding

adwelds' original ultrasonic system allows welding CFRTP continuously with high rigidity

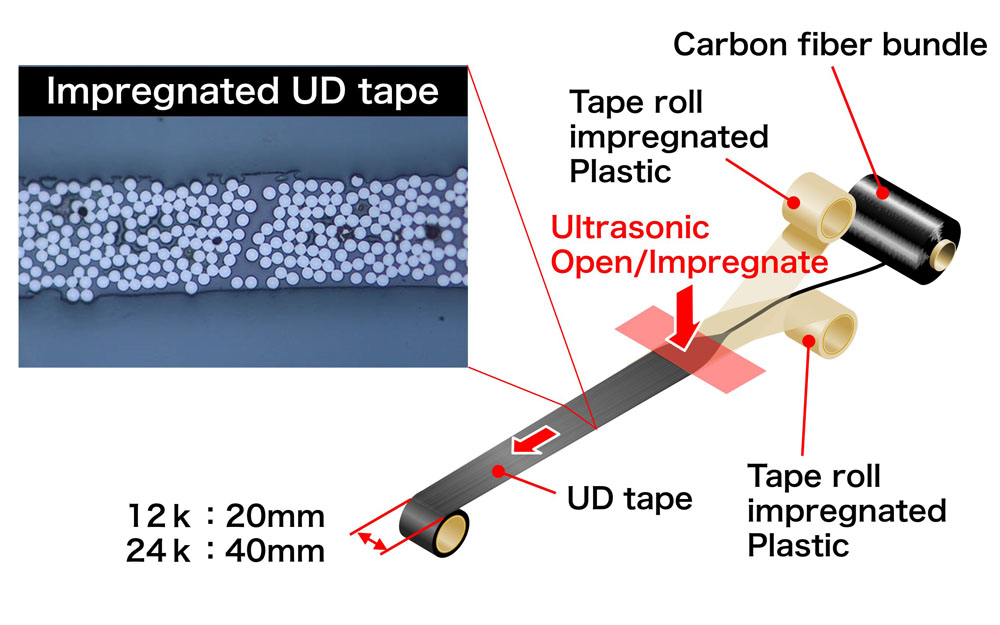

CFRTP-UD Tape (Leveling/Impregnation)

adwelds supply a tape type material of impregnated resin which is easy to handle, and ultrasonic completely dissolves thermoplastic resin that has high viscosity

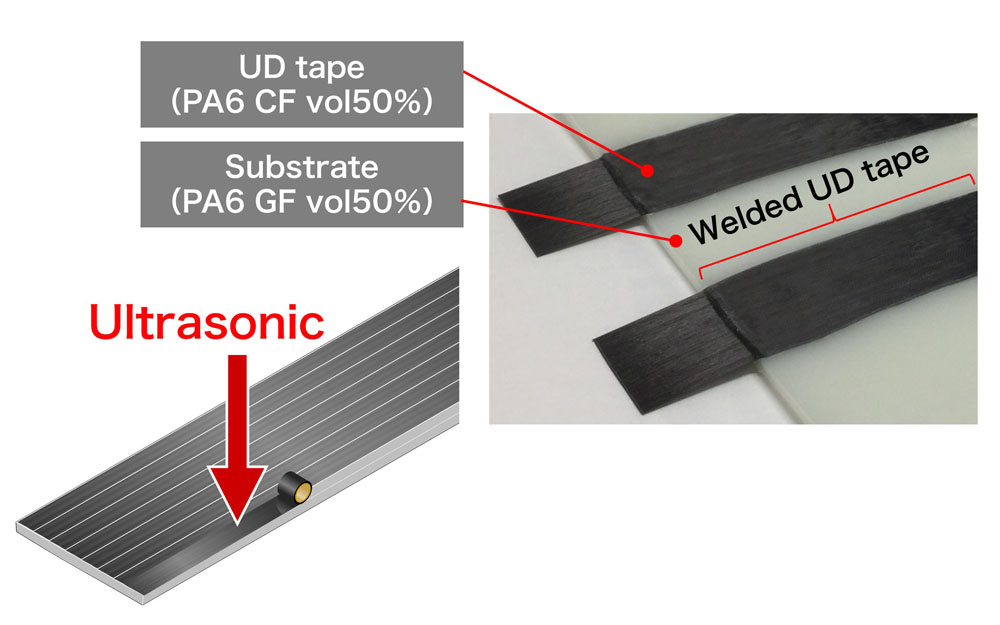

CFRTP-UD Tape Lay-up

Ultrasonic rigidly welds a UD tape on a resin coated substrate. It contributes to improve the rigidity of resin products