adwelds thinks it is important to maximize the characteristics of high functional materials, which have a wide range of usage in the manufacturing process. Utilizing adwelds' advanced ultrasonic bonding, ultrasonic cutting and ultrasonic welding in the manufacturing processes will lead to increase clients' production value. adwelds' advanced ultrasonic machines install functions to set prcessing conditions digitally and/or to monitor each process appropriately.

Ultrasonic Cutting Process

Ultrasonic Welding Process

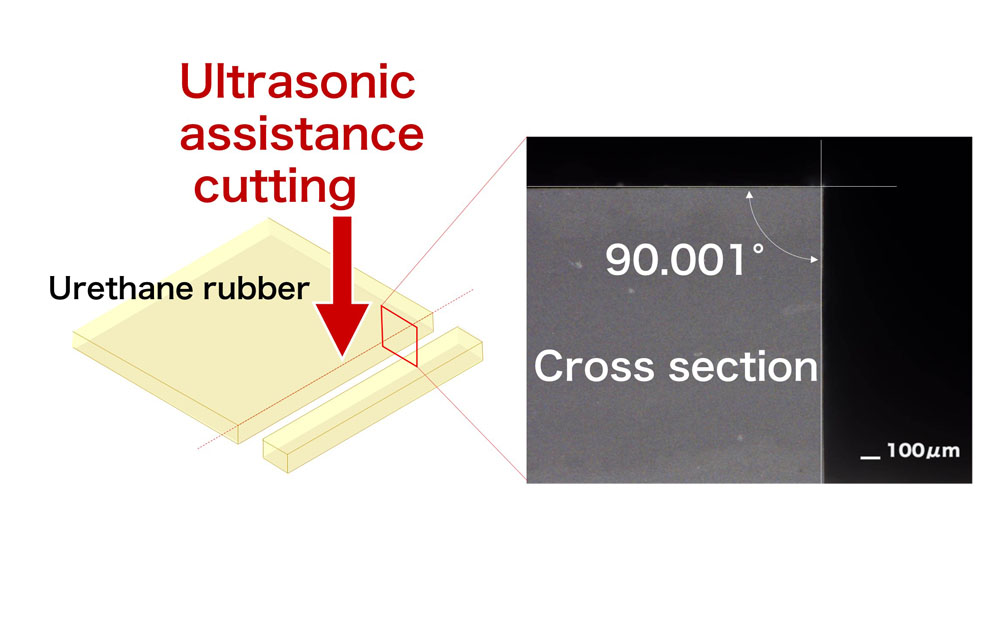

Urethane Sheet (High precision shape cutting)

Ultrasonic helps to control deformation when bonding a soft material and realizes a high precision sectional cutting

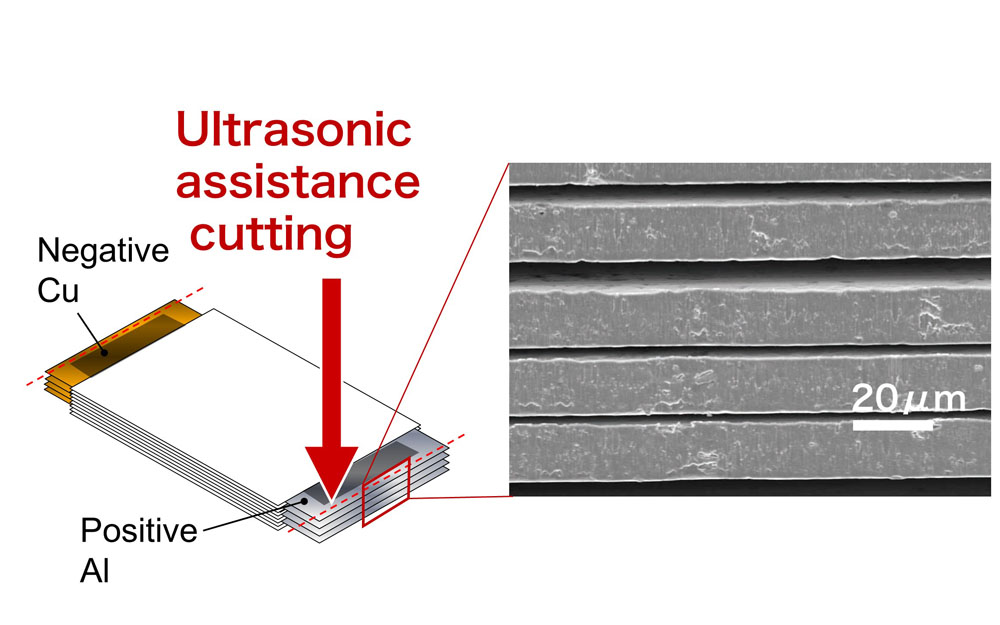

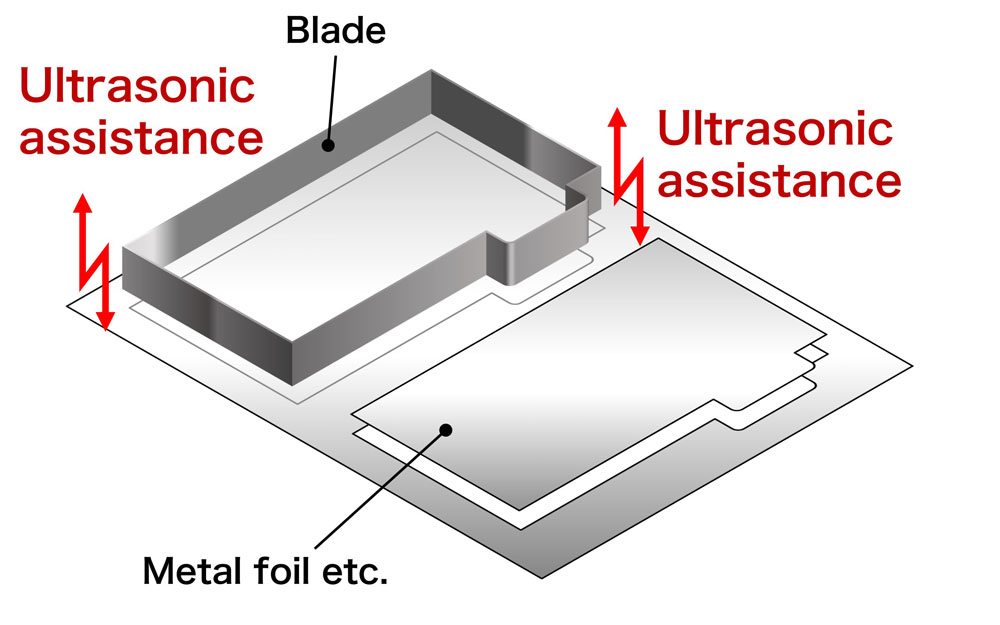

Li Ion Battery (Multi Layer Cutting)

With a conventional cutting technology, burrs and warpage occurred during bonding, but ultrasonic prevents metal foils from deforming and cuts smoothly

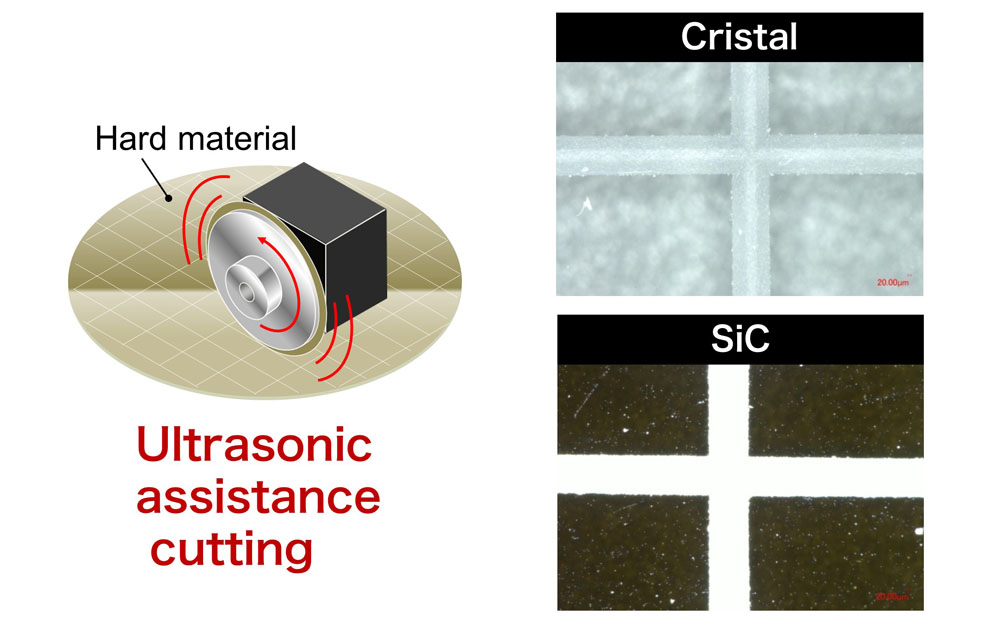

Cutting Hard Materials

Ultrasonic helps hard materials from chipping and allows high quality cutting

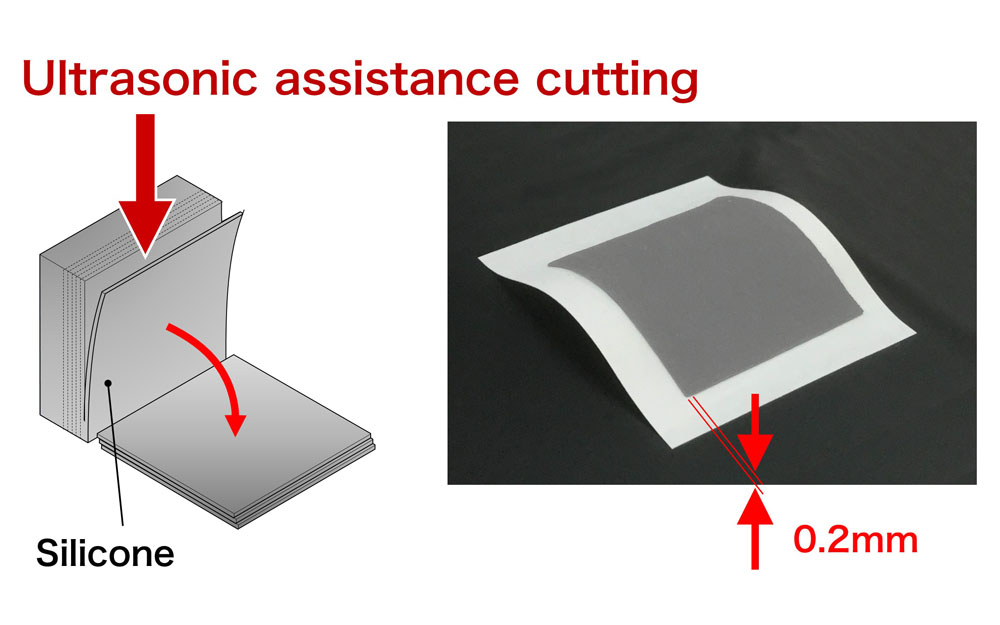

Cutting Silicon Thinly

Ultrasonic controls an elastic application to deform when cutting, so it can even slice an application with a thickness of 0.2mm

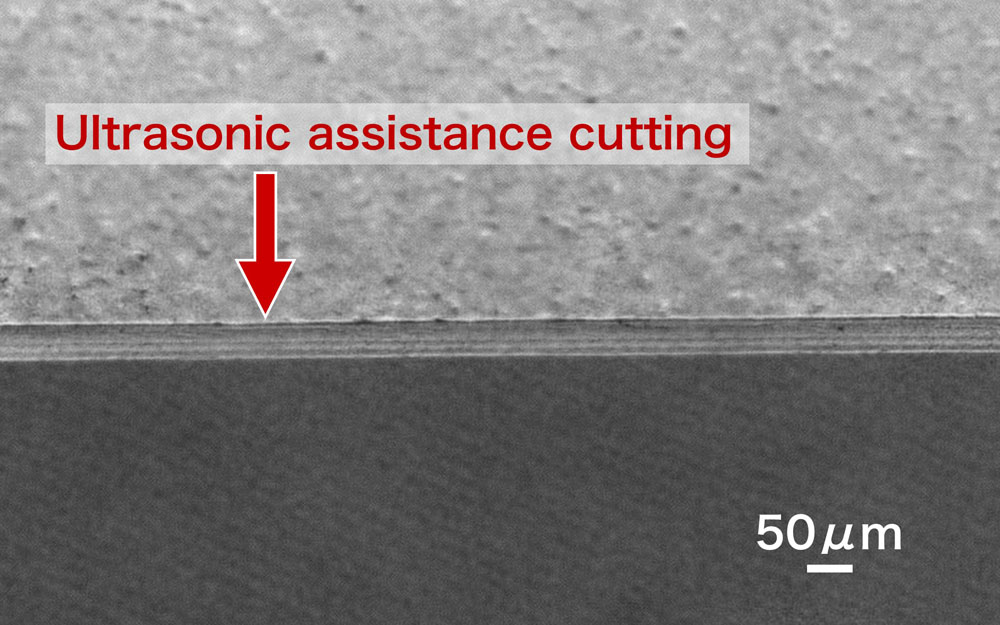

Resin Film (High Quality Full Cutting)

Ultrasonic can cut 50μm film with a beautiful cross section

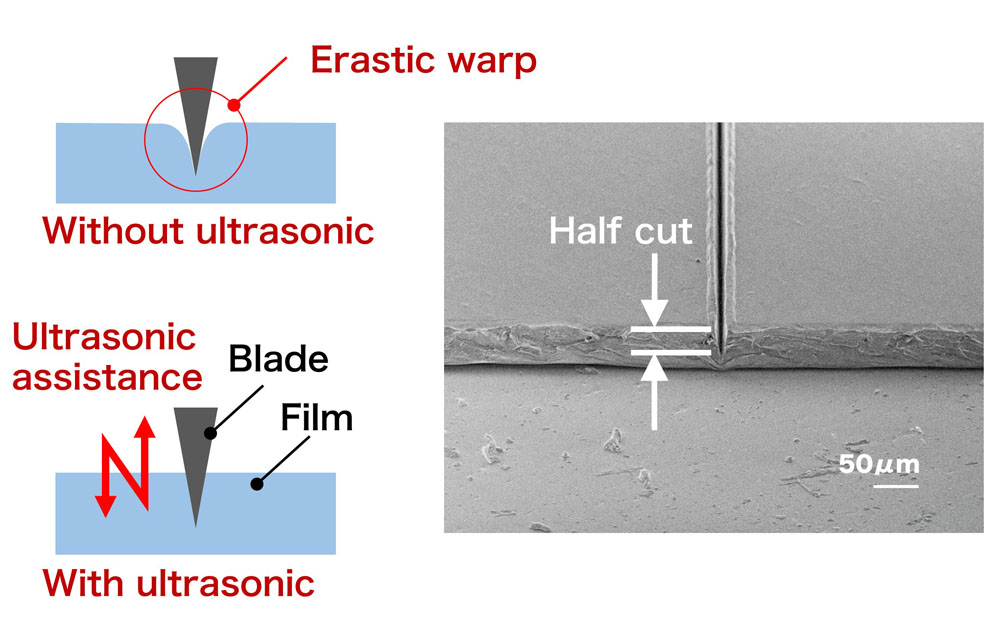

Resin Film (High Quality Half Cutting)

With a conventional cutting technology, a film deformed when cutting and was difficult to achieve a half-cut, but with ultrasonic assistance, it controls the film to deform and obtains stable half cutting

Dieless Shape Cutting with Mold

Bring the initial cost down to 1/10 with our cutting tools

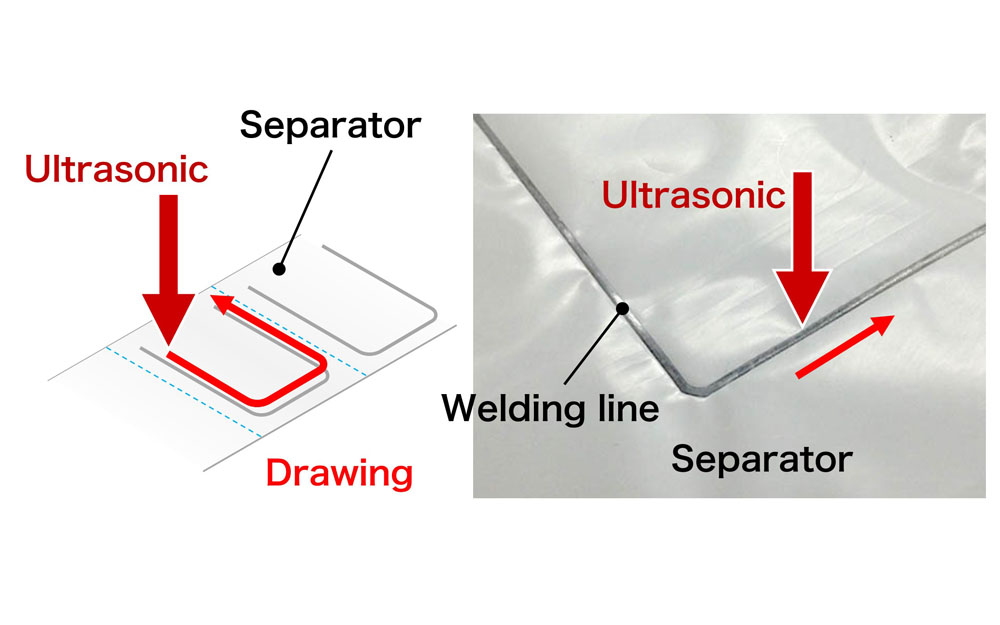

Li Ion Battery (Seperator Welding)

A seperator, which is weak to heat, can be welded by pressing (the pressed part only dissolves) and applying ultrasonic without heating

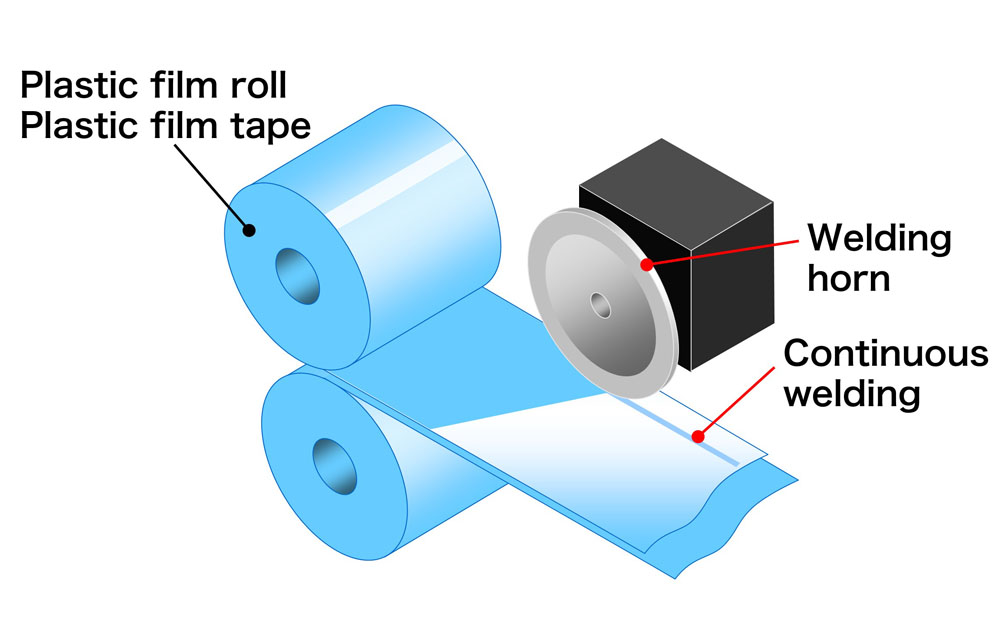

Continuous Welding

Use a rotary horn and weld a roll type resin material continuously