adwelds provides ultrasonic advanced machines that cope with changes in materials or manufacturing processes to improve quality of semi condutor/electronic components. Utilizing adwelds' advanced ultrasonic bonding and ultrasonic cutting in the manufacturing processes will lead to increase clients' production value. adwelds' advanced ultrasonic machines install functions to set prcessing conditions digitally and/or to monitor each process appropriately.

Ultrasonic Bonding Process

Ultrasonic Cutting Process

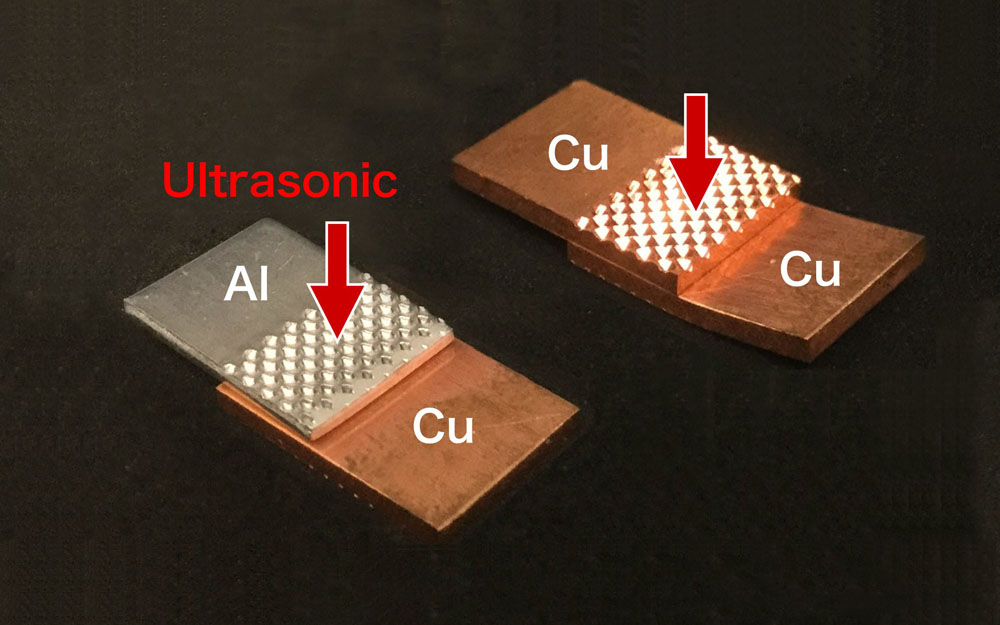

Homogeneous/Heterogeneous Metal Bonding

It bonds heterogeneous metals well, which was hard to achieve with conventional bonding method. Needless to solder, you can bond them directly at room temperature

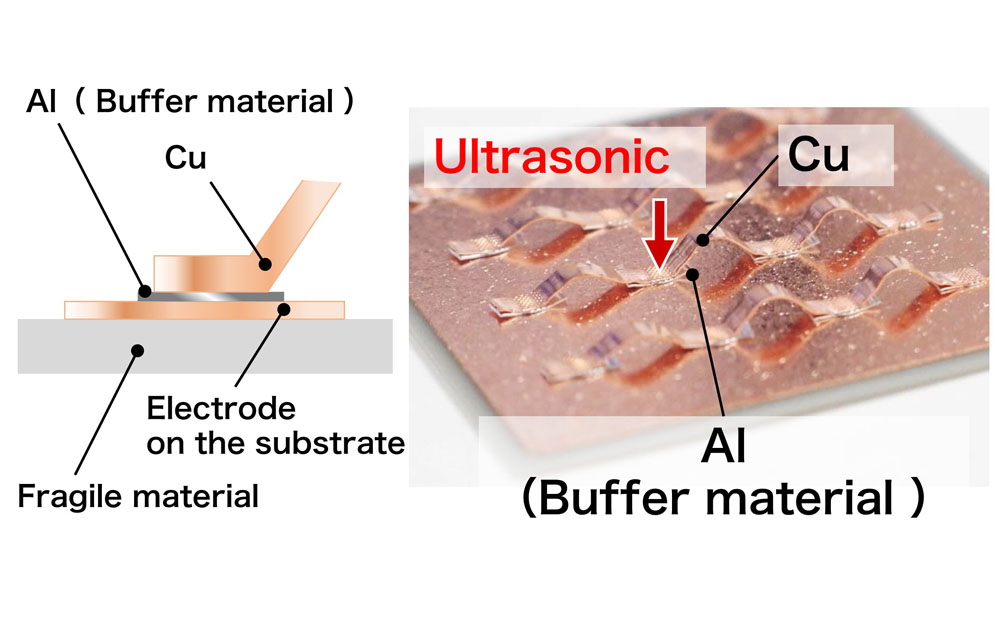

ABB Process

Cu ribbon bonding is available by using Al as a buffer material, it gives strength to a feeble base material

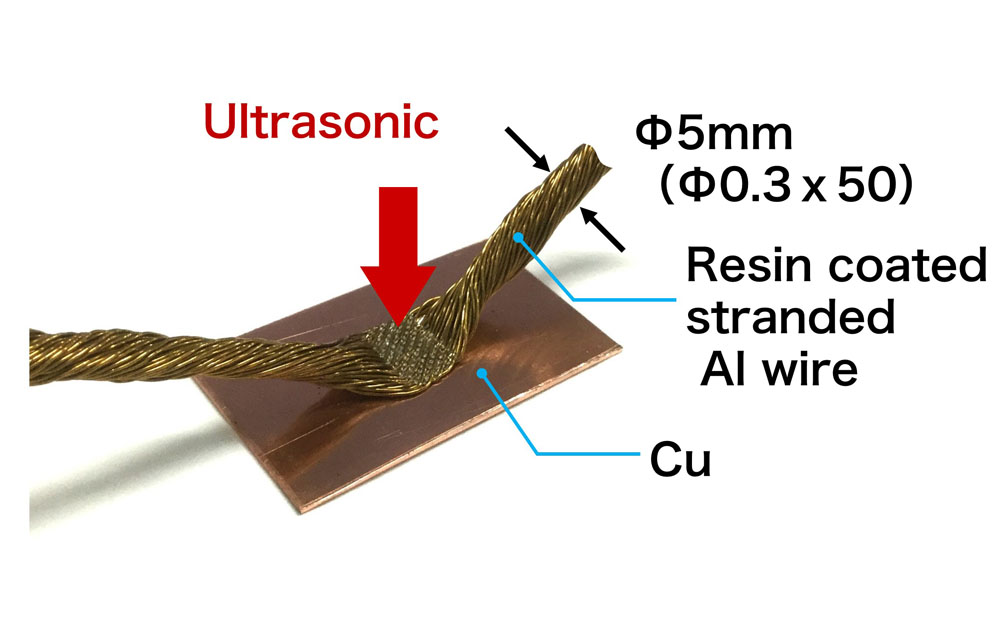

Bonding Coated Wire

After pressing down the coated wire, ultrasonic breaks the insulating layer and bonds the inner wire to an electrode directly

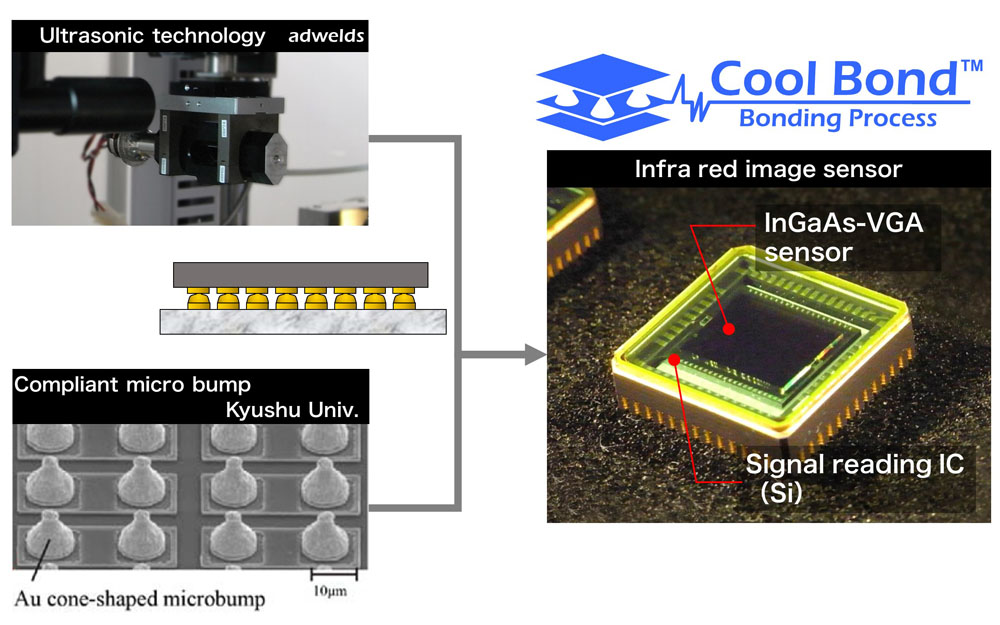

Infrared Image Sensor (Cool Bond)

Our ultrasonic bonding machine bonds 300,000 sharp-end bumps (Kyushu U) at once at room temperature, a collaboration with Kyushu University

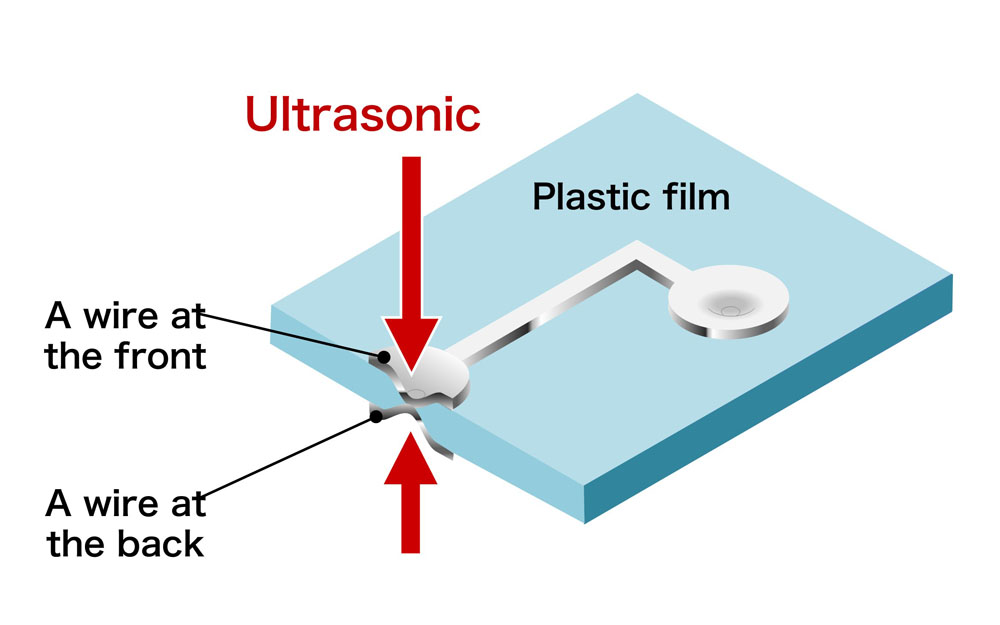

IC Card (Front and back pattern pierce bonding)

When pressing down the wirings on the resin film and apply ultrasonic, ultrasonic pierces the film, without pretreatment of via processing, it bonds the wires

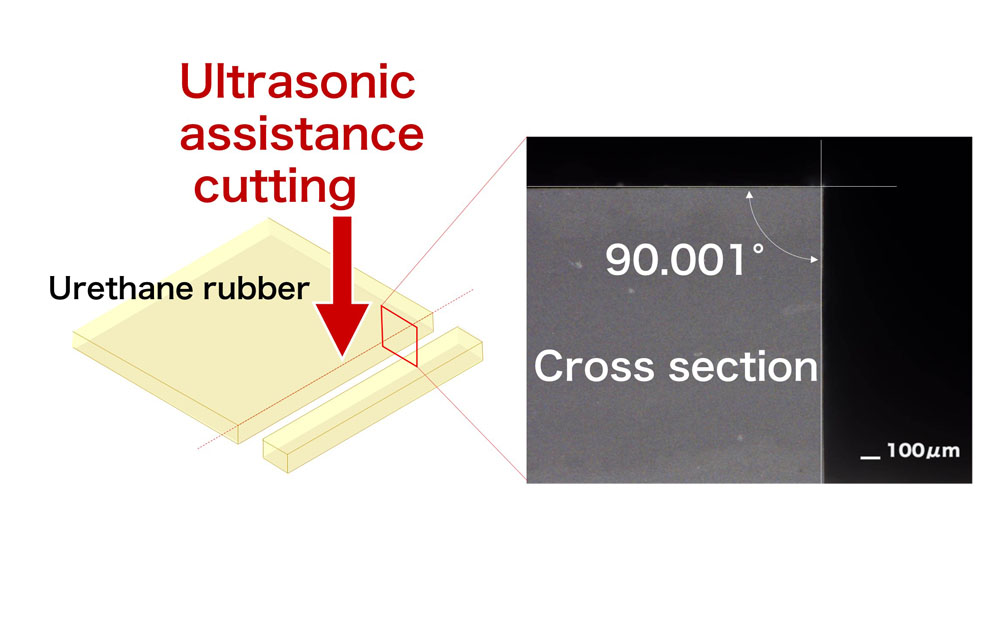

Urethane Sheet (High precision shape cutting)

Ultrasonic helps to control deformation when bonding a soft material and realizes a high precision sectional cutting

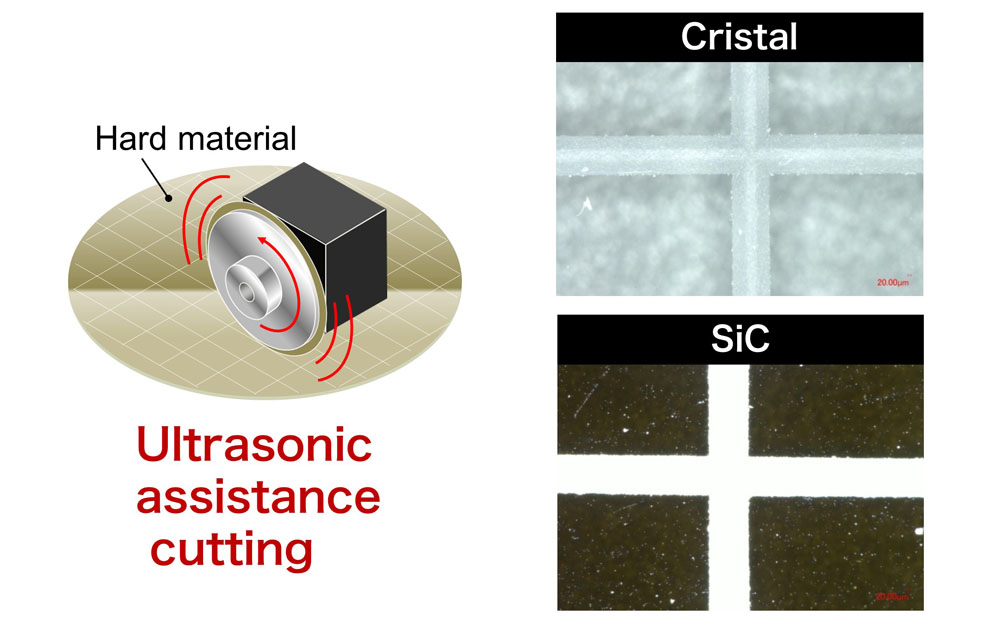

Cutting Hard Materials

Ultrasonic helps hard materials from chipping and allows high quality cutting

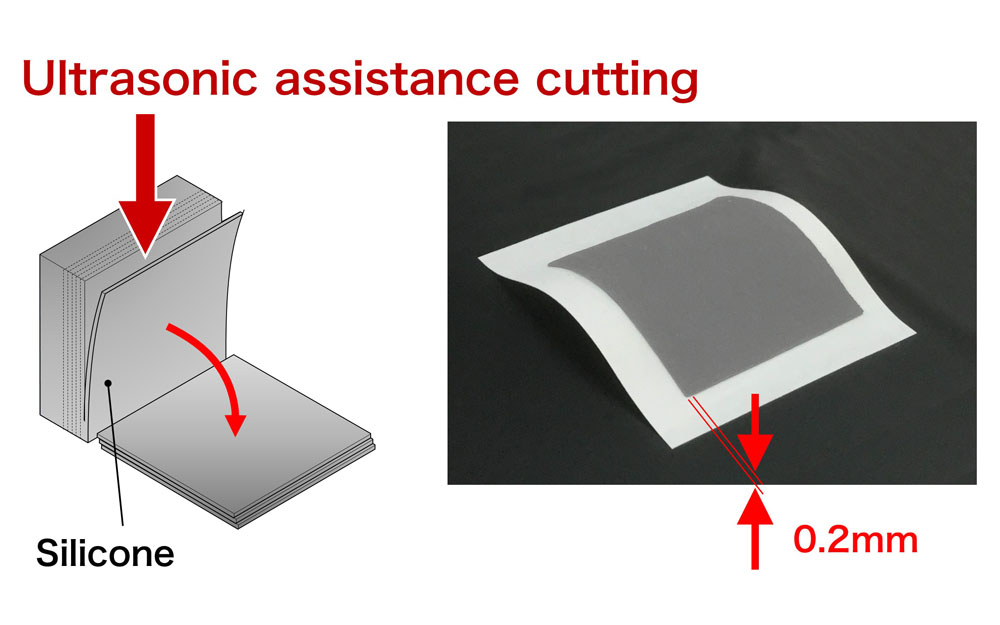

Cutting Silicon Thinly

Ultrasonic controls an elastic application to deform when cutting, so it can even slice an application with a thickness of 0.2mm

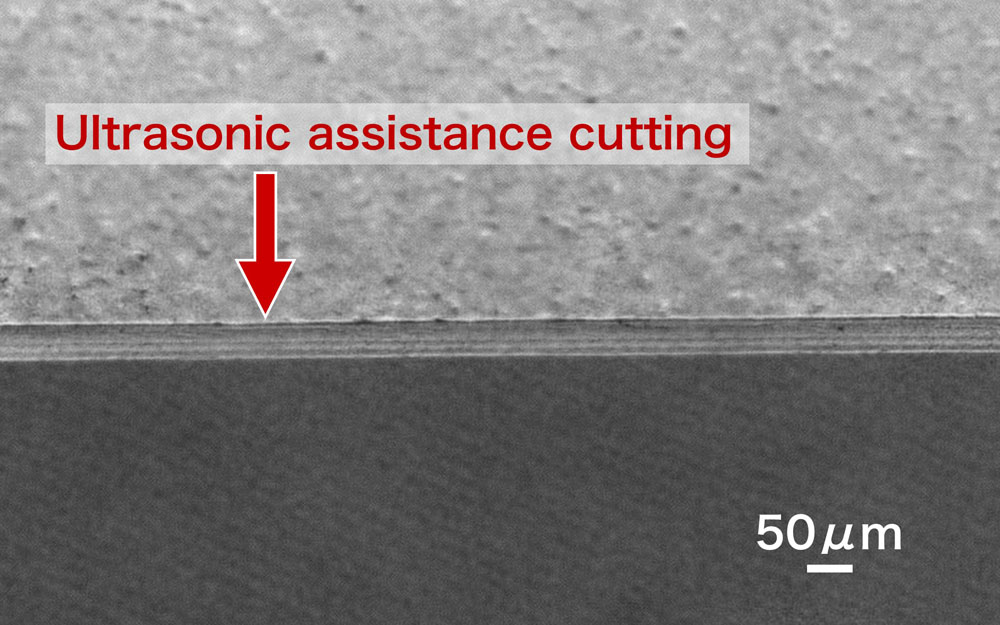

Resin Film (High Quality Full Cutting)

Ultrasonic can cut 50μm film with a beautiful cross section

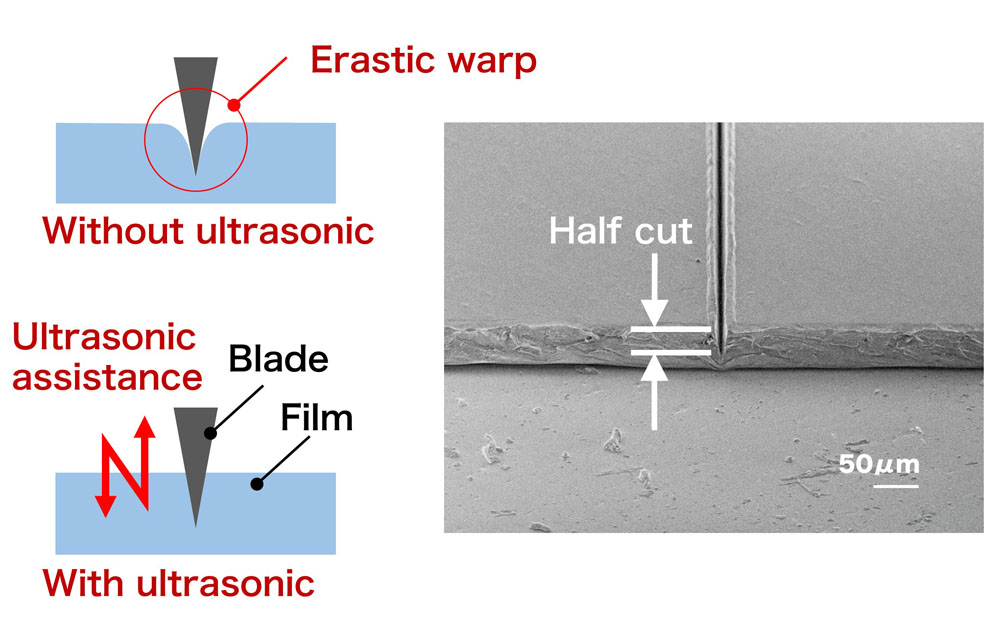

Resin Film (High Quality Half Cutting)

With a conventional cutting technology, a film deformed when cutting and was difficult to achieve a half-cut, but with ultrasonic assistance, it controls the film to deform and obtains stable half cutting

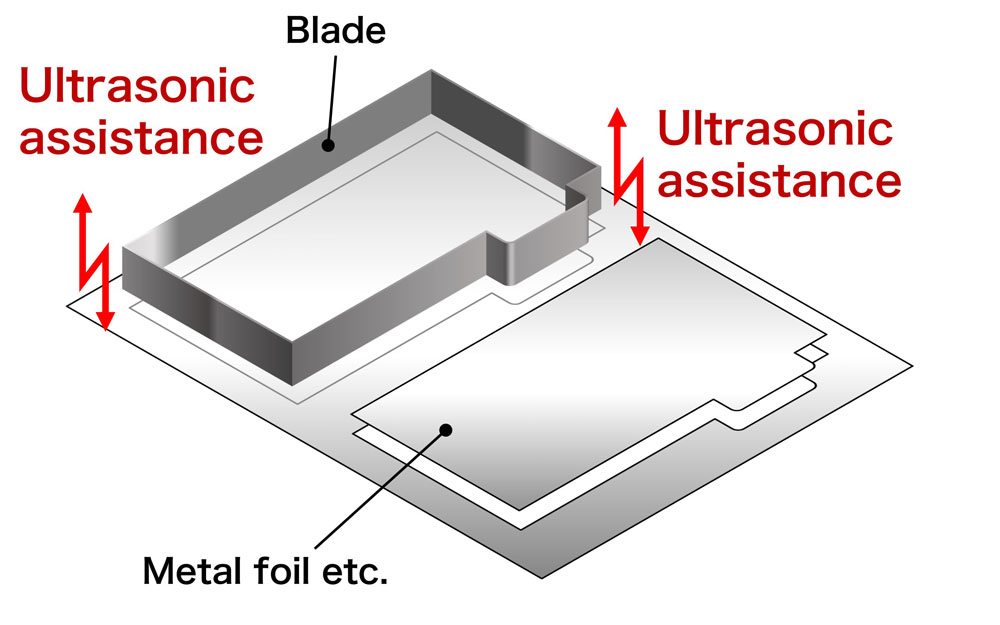

Dieless Shape Cutting with Mold

Bring the initial cost down to 1/10 with our cutting tools