adwelds provides ultrasonic advanced machines that cope with changes in materials or manufacturing processes to improve Li Ion batteries and IGBT modules. adwelds suggests clients various ultrasonic bonding, cutting, and welding for processing. By utilizing our advanced ultrasonic technology will highly improve clients’ production value. adwelds' advanced ultrasonic machines install functions to set prcessing conditions digitally and/or to monitor each process appropriately.

Ultrasonic Bonding Process

Ultrasonic Cutting Process

Ultrasonic Welding Process

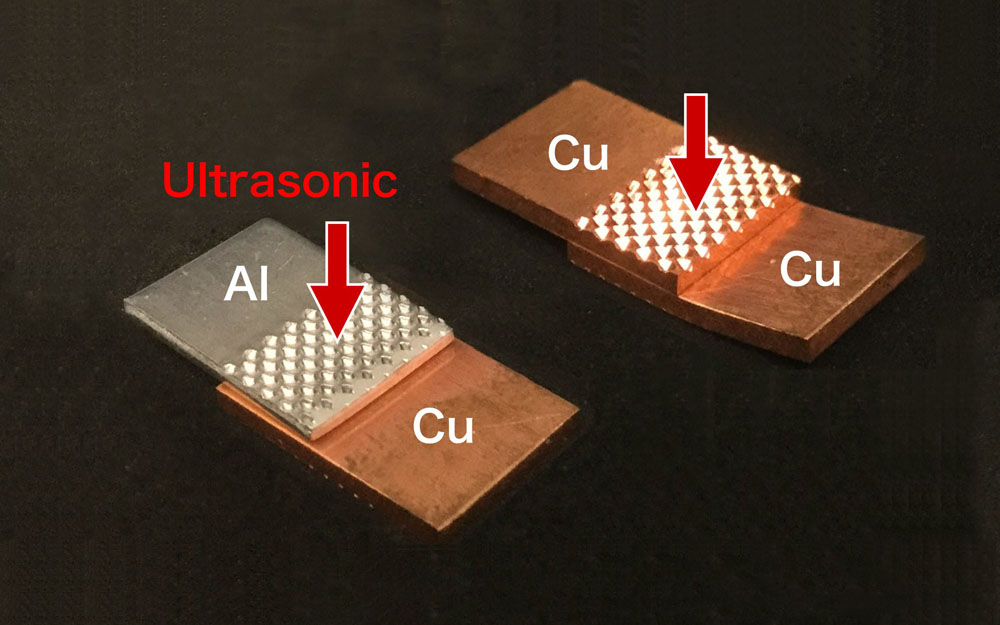

Homogeneous/Heterogeneous Metal Bonding

It bonds heterogeneous metals well, which was hard to achieve with conventional bonding method. Needless to solder, you can bond them directly at room temperature

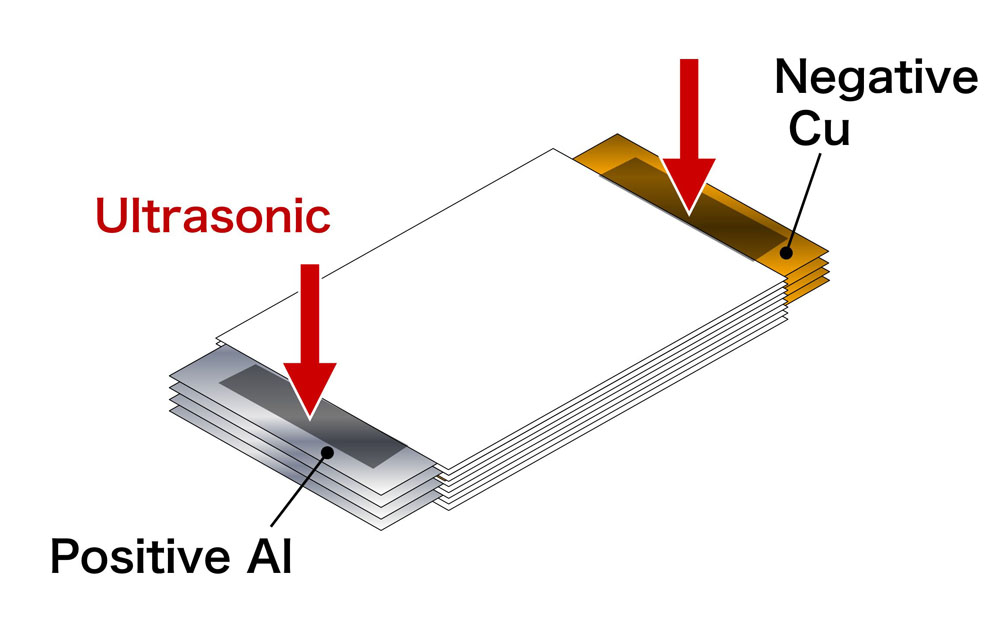

Li Ion Battery (Multi layer foils)

Li Ion batteries are weak to heat, but ultrasonic bonding allows bonding over 50 layered foils without heating

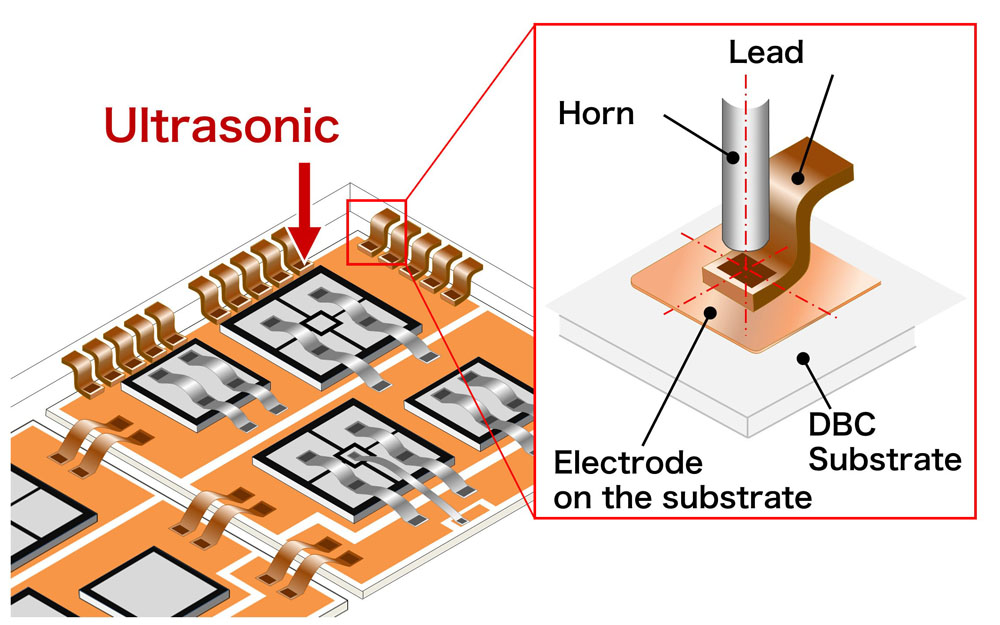

IGBT Module (Terminal bonding)

It is desirable to bond without soldering when dealing with IGBT module, which requires high temperature during operation. Ultrasonic bonds the lead on the package side and the electrode on the DBC substrate directly

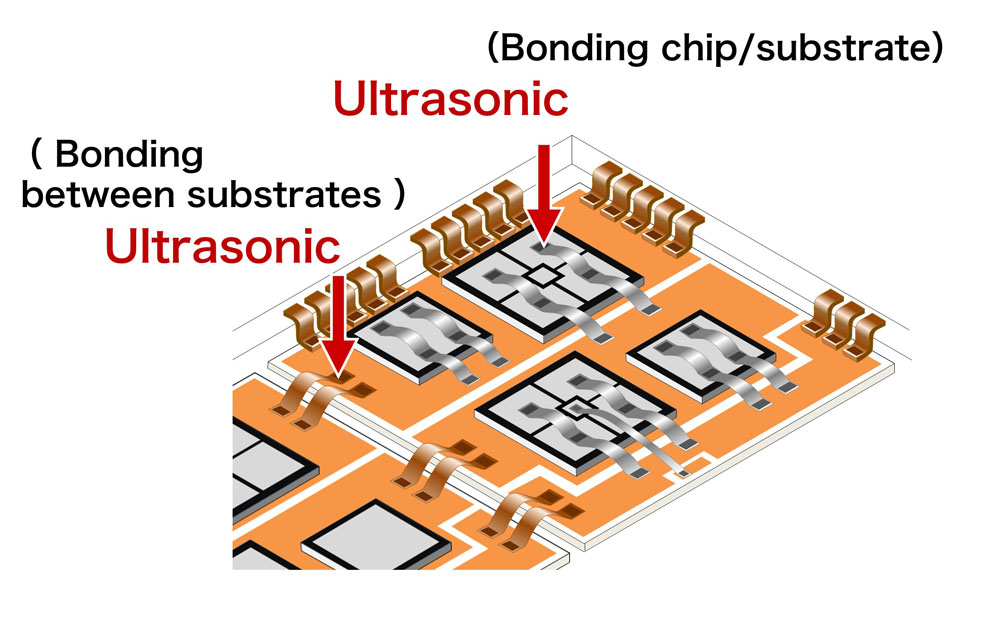

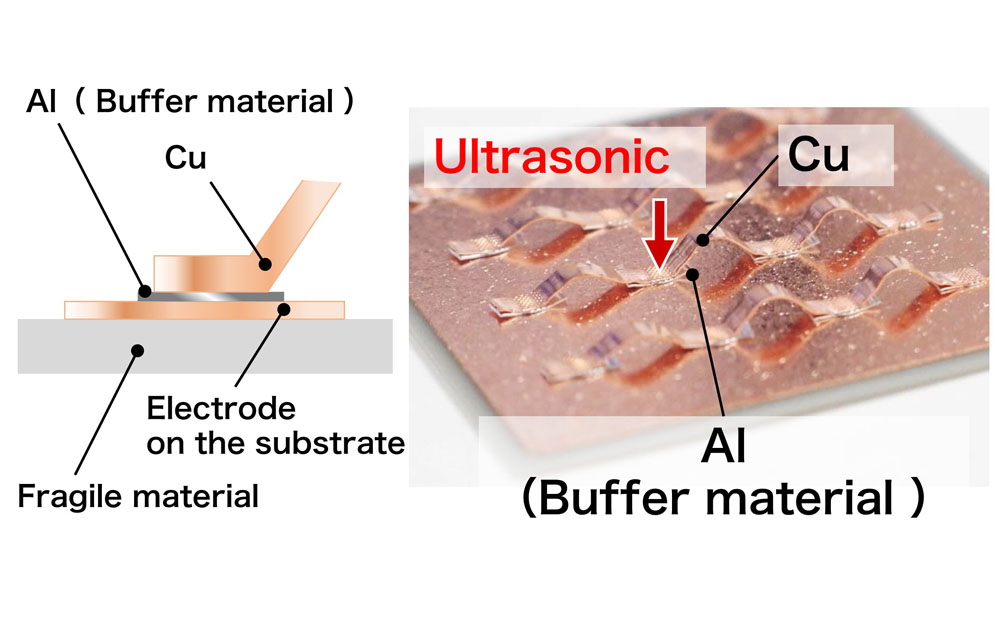

IGBT Module (Ribbon Bonding)

Multiple kinds of ribbon bondings are available with multi-feeder

ABB Process

Cu ribbon bonding is available by using Al as a buffer material, it gives strength to a feeble base material

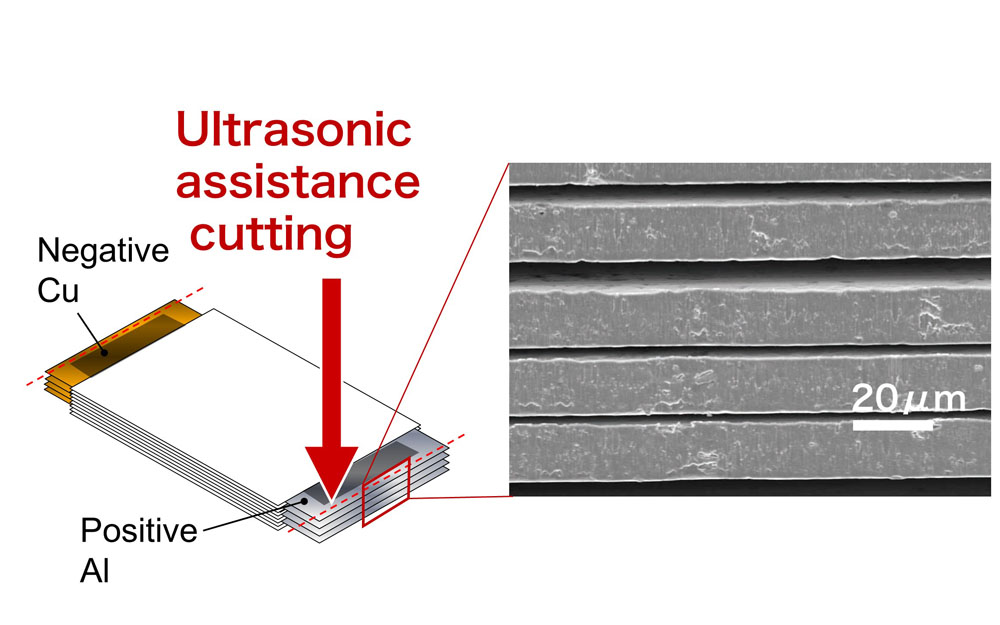

Li Ion Battery (Multi Layer Cutting)

With a conventional cutting technology, burrs and warpage occurred during bonding, but ultrasonic prevents metal foils from deforming and cuts smoothly

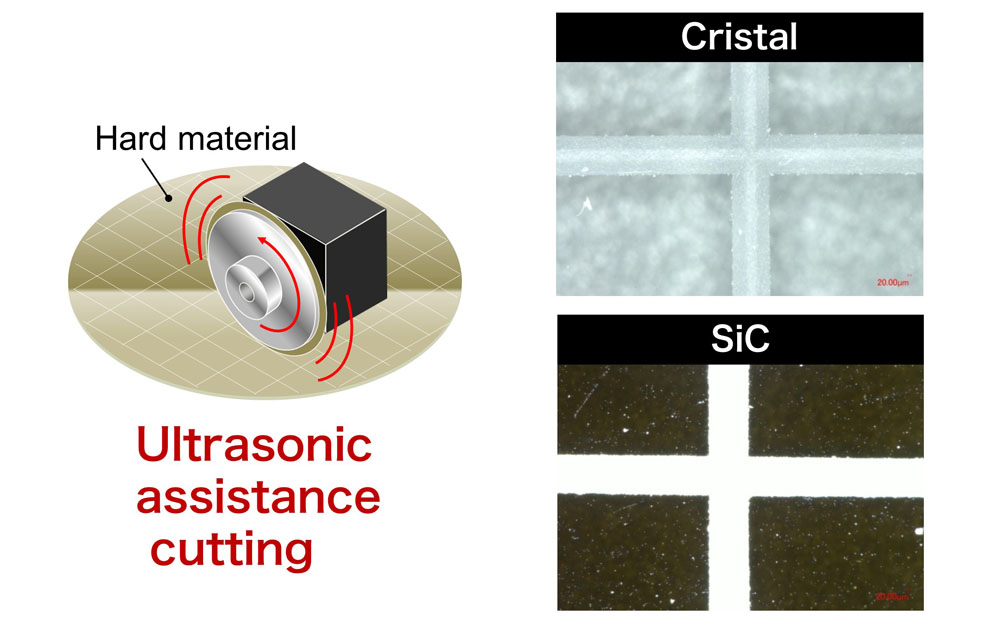

Cutting Hard Materials

Ultrasonic helps hard materials from chipping and allows high quality cutting

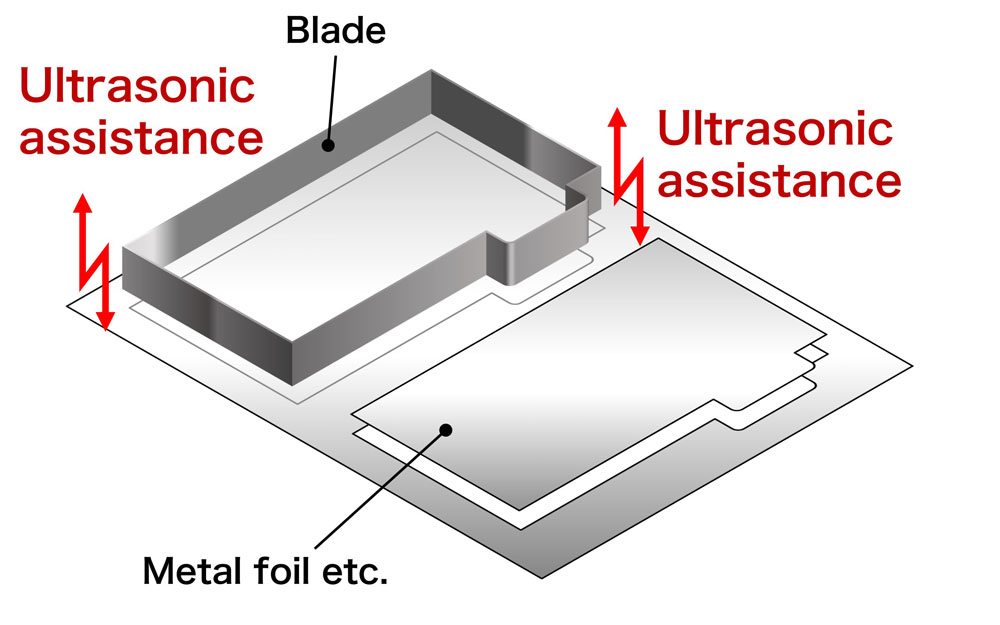

Dieless Shape Cutting with Mold

Bring the initial cost down to 1/10 with our cutting tools

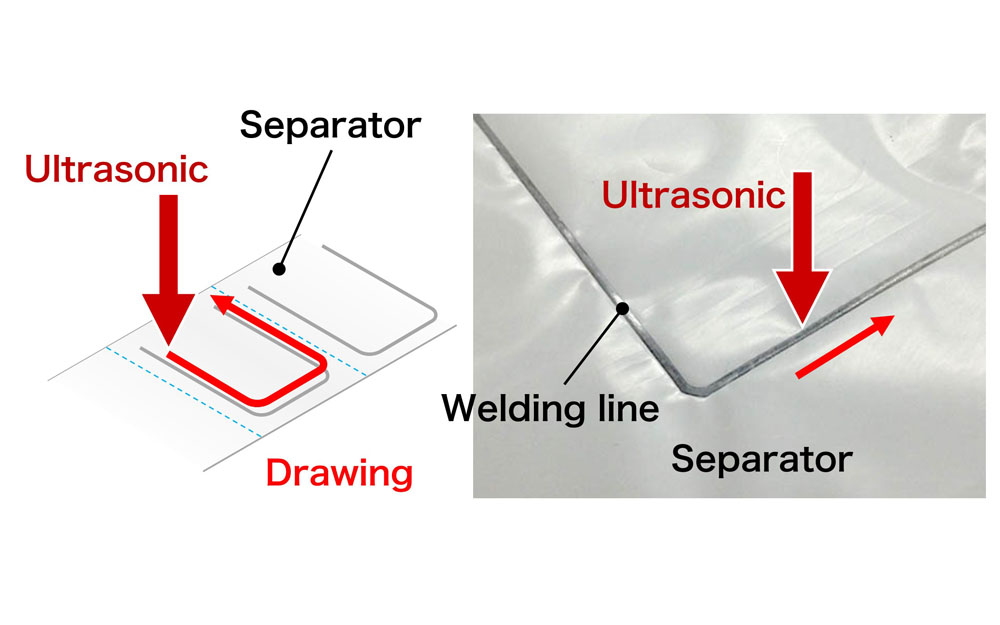

Li Ion Battery (Seperator Welding)

A seperator, which is weak to heat, can be welded by pressing (the pressed part only dissolves) and applying ultrasonic without heating